All manufacturers want to have such machine which can fulfill their requirement completely. But due to some constraint in conventional machine they have to process a bit longer period to get their final product. This happens every time when we have to process the product on conventional machine. SPM on the other hand eliminate this kind of problem and reduce time for manufacturing.

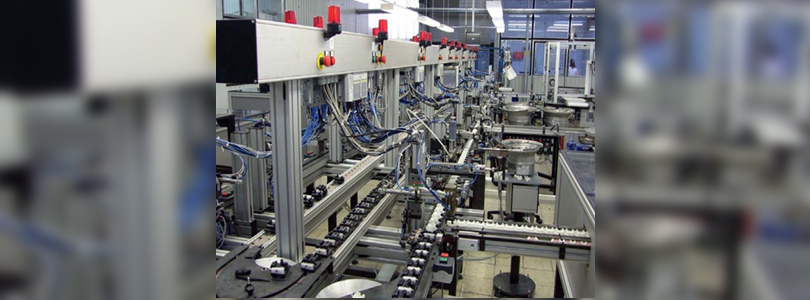

Special Purpose Machines (SPM) are designed to perform some specific applications which cannot be carried out using conventional machining processes.

Special Purpose Machine (SPM)….?

The need of Special Purpose Machines (SPM) is to perform tasks at very high rate. The purpose is defined first. The constraints are listed. The machine is designed to fulfill the purpose along with the constraints.

Therefore they are made as per the customer’s specific requirements. Another advantage of using SPM is to minimize possibility of human error and also reduces human fatigue during repetitive operations again and again. SPMs or Special Purpose Machines offer immense scope for high volume production at low investment and at low cost of production when compared to conventional machines. SPM with specially designed tooling and fixture is used for mass production of the same component. A sensible combination of limit switches, sensors, logic controls, automatic job clamping etc. are the elements of a SPM.

A machine out of variety of index machines is chosen to suit the given requirement. Indexing unit used in presses, drilling machines has number of indexes, speed of index and dwell time can be readily changed in this mechanism. It is operated by fluid power and uses ratchet and pawl mechanism.

These tools are designed to perform special machining operations, usually for production purposes. Examples include gear cutting, gear grinding machines, broaching machines, lapping and honing machines, boring machines etc.

Automated production techniques are widely used in manufacturing industries for dealing with issues such as high cost of labor, Shortage of skilled people, Low interest of labor to work in production firms, safety, improve quality and high cost of raw materials.

Different layouts of SPM:

Generally there are two layouts for SPM:

- Single station

- Multi station

In single station the work piece is held in fixed position where machining and sliding units are positioned around it such that they can process the part from different directions.

In multiple machining units they may process the part simultaneously or in sequence depending on the geometry of the work piece and machining features.

Various Types of SPM:

Generally there are two layouts for SPM:

- SPM for metal cutting.

- Special purpose CNC machine.

- SPM for vertical turning machine.

- Rotary indexing drilling and tapping SPM.

- SPM for multi and simultaneous operations such as drilling, milling, boring etc.

In the production process, there’s continuously a requirement to enhance the standard of Product, minimize rejection and increase the productivity per person, to cater to the pressing circumstances in the GLOBALISED WORLD ECONOMY.

Special Purpose Machines (SPM) giving very High Productivity. The theme can be further elaborated by doing a full scale automation of the industrial process, wherever possible. It assures the quality and interchangeability of parts, by carrying out the same designed process each time without any shortcuts.

The Special Purpose Machines (SPM) is designed to operate continuously for 24 hours a day, with minimum supervision. The Special Purpose Machines are generally Product Specific & they are required to be Designed & Developed for specific requirement. Sometimes it may be possible to cater to the Jobs having similar features but differing in dimensions by change tooling concept.

Special Purpose Machines (SPM) is either Cam Operated Machine or they use hydraulics or pneumatics as actuating elements or combination of all the three of them. Many times Programmable Logic Controller is used in conjunction with Positional Sensors & Transducers, to give commands to the actuating elements. Sometimes different motors like Stepper Motor & Servo Motors are used as actuating elements. The productivity achieved after all these efforts is very high. Productivity of 3 to 10 times is achievable. However to fetch the fruits of these highly specialized machines the precondition is that the input to the automatic machine must have strict quality control.

We conceptualize the system design understanding the customer needs or requirements with a collaborative approach and develop the machine.