Model-based Definition (MBD) approach is very popular in various industries. MBD is a process in which a 3D CAD model contains the complete product and manufacturing information such as GD&T display and other annotation behaviors within the solid model

Before professional organizations used 2D drawings to deliver product manufacturing information even as they designed models in 3D. But Now MBD is acting as a single, reliable source of truth for the whole extended team. It prevents errors and saves everybody time.

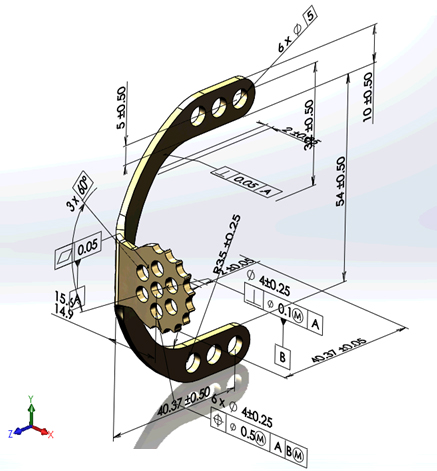

MBD communicate to user a complete product and manufacturing information directly in 3D, eliminating the need for 2D drawings and gained new capabilities, such as applying dimensions, datum features, GD&T, notes and other product details. MBD may contain enough information to manufacture and inspect product without the need for engineering drawing.

It can also now import parts with 3D annotation from other CAD systems such as Creo, NX and CATIA as well as STEP AP242.

Before unintended hole scrapped the entire part because there was no cost-effective way to fill it up and make it blind again. The root cause was that the drawing sent to the supplier missed a hole depth. Without the depth, a hole defaults to a through-cut in drawings.

Rather than creating perfectly matched drawings separate from the models, we need to bypass drawings and put MBD directly as one document?

MBD increases technical communication efficiencies:-Drawing based approach always required more clarification so more communication is required rather than model-based approach don’t have questions during its machining and inspection work. MBD provides a 3D presentation rather than a 2D abstraction.